【适应超高速设计】

|

| [Design by high speed] |

| 强韧的两侧箱形机架和把横梁作为主体的高刚性机架构造即使是织造厚重织物的超高速运转,其对震动的抑制和耐久性都是超群的。也能进行稳定的打纬,织造出高质量的高密度织物产品。 |

| Durable two side box frame and the structure of 4 horizontal beam with high angular rigidity,even weave weight cloth at high speed,the restraint of shake is preeminent.Also can proceed stable beating up and weave is high quantity. |

|

|

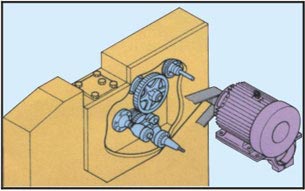

【保证了实行完全加油的循环系统】

|

| [Guaranteed the circulatory lubricate system] |

| 在主传动、送经、卷取、打纬和凸轮机等主要传动部分都采用了油浴方式。另外,其他的加油部位也采用了强制集中加油和加注黄油,从而大幅度延长了加油的间隔时间并简化了保全的作业。 |

| At main driving,let-off,take-up and cam shedding etc.,These device adopt oil bath.Moreover,the other parts also adopt to concentrate lubricate with the butter,so extension partition time to add to oil,and maintain get to easy. |

|

【电控自动集中加油系统(选件)】

|

| [Auto concentrates lubricate system(choose part)] |

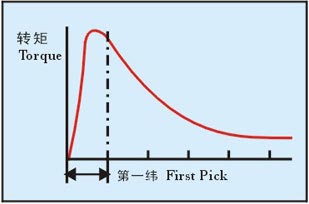

【动力·超启动电机】

|

| [Driving-Rush start motor] |

| 独立的超启动系统,使织机在启动时可以产生8倍于通常运转时的转矩,以提高第一纬的打纬力量,防止停车档的产生,适用于对高质量织物的织造。 |

|

| Independent super start system can produce 8 times torque than usually at start,it can increase the power of the first bating-up and prevent weft crackiness.It suit to the high quantity clot. |

【图文显示中/英文i键盘】

|

| [Diagram text manifestation English i- keyboard] |

| 根据操作工和保全工的作业情况,通过图文显示i键盘上4个不同的功能的操作键(监视、控制、服务和计数),可以选择根据作业情况的显示内容。 |

| According the condition of operator and fixer,can use four function key (surveillance,control,service and count)on I-keyboard,can choose according to the work content. |

FILLING

|

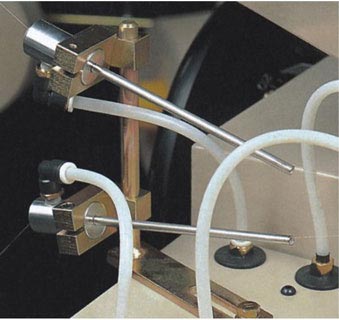

【探纬器】

|

| [Feeler] |

| PS109e用于长丝的有一个探头,用于短纤的有两个探头。可探知通常的短纬和被吹断纬纱。高性能反射式探纬器可进行广泛围的探测,做到有效保护。另外,探头头部耐脏污强,具有非常高的可靠性。 |

| Ps109e use one feeler for filament,used two feller for spun.Besides exploring usually short pick,can also explore the break pick.The high performance echo sensor can proceed extensive exploration,attaining absolutely safe.Moreover,the sensor bears the dirt strong,have very high dependable. |

|

|

【AJC引纬的自动控制装置】

|

| [AJC--Automatic control equipment for filling] |

| PS109e装备了AJC引纬自动控制装置,该装置是由计算机监视纬纱到达探纬器的时间,并对其变动通过引纬定时的控制进行补偿的系统。特别是对从满卷到小卷过程中的退绕张力的变化大的纬纱效果明显。实现了稳定的引纬。 |

| Ps109e equipment AJC,that device watch arrvie time of pick by computer,according its change to adjust filling time.Especially obvious effect for change tension from full beam to small beam.Realizes to stable filling. |

【稳定引纬的措施第一纬控制】

|

| [Measure for stable filling:The first filling control] |

| 织机启动时的第一次引纬因转速与通常相比较为缓慢,容易产生长纬或沙短不良等引纬故障。PS109e采用电脑单独控制第一纬的引纬定时,防止启动时的长纬或短纱端的故障。 |

| When the loom start,the first filling time is slow than usually,it easy creation long pick etc..PS109e adope computer controls alone the first filling,prevent long pick to stop. |

【APF自动对梭口】

|

| [APF auto to shuttle] |

| 在发生引纬失误时,织机在引入下一根纬纱前停止,进行自动反转并停止在设定位置。失误纬纱的处理和在启动的操作非常容易,可以防止操作的失误并可以增加看车台数。 |

| At take place filling error,the loom can stop before next filling and proceeding auto reversal,finding out the shuttle of the trouble pick and stop.It is easy to handle trouble pickand run again,can keep the error of operation and can increase operating number of loom. |

【FDP电子储纬装置】

|

| [FDP electronic storage pick device] |

| FDP电子储纬装置中,向鼓筒卷绕纬纱的导纬器的旋转和织机的转速是完全同步的。同时,止纱的纱销的运动也是由计算机进行控制,因此即使变更织机的转速,也无需再次调整FDP。 |

| In FDP electronic storage pick device,winding pick is complete synchronous with loom speed.At the same time,the pin is moved by computer control,therefore change loom speed,also need not adjust the FDP again. |

【辅助主喷嘴】

|

| [The assistance main nozzl] |

| 加强纬纱的输送力,即使是在超高速或宽幅织造等不利于纬纱飞行的条件下,也可以减少断纬,停止运转。除有和主喷嘴联动的标准型以外,还有可任意设定喷射定时的独立控制型。可选装WBS纬纱张力疏解于拉直装置。 |

| Let pick proceed the acceleration at low- pressure,can prevent harm yarn,even at super-speed or super-wide,also can easily stable filling,Besides there are standard type of associate with main nozzl,still it has can set up independent controltype for jet. |

|

【辅喷嘴的分别喷射控制】

|

| [Respectively control of sub nozzle] |

| 对于不同种类的纬纱,利用设定分别的喷嘴与该纬纱相匹配的辅助喷嘴喷射的定时,实现了稳定的运转,提高了织物的产品质量,节约了能源。 |

| For different kind of pick,made use of distinguish jet time of sub nozzl,realizes to stable filling,increase the quantity of fabric,energy saving. |

【高速有余地的引纬及大力打纬】

|

| [Super-speed and filling enoughly ] |

| 对于窄幅,采用4节连杆打纬,从而实现了即使在高速也能进行的稳定引纬。280cm以上宽幅采用了6节连杆打纬,从而实现了稳定引纬;实心摇轴加强了打纬力量。 |

|

| For the narrow,because of adopting four connecting link beating-up with excellent evaluation,thereby realizes stable beating-up even in the high speed. A 6-link beating motion is used for wider looms.Above 280cm. |

LET OFF

|

| 由于采用了高刚性的构造体,配装了大直径的经轴齿轮和装配了滑动轴承的张力拉杆,可以灵敏的对应利用高速织造的高密度织物。 |

|

| Because adopting high rigidity structure,equip big diametral warp beam gear and equip tension cross rod,can intelligent to weave weight fabric at super-speed. |

【保持经纱张力均匀的ELO电控送经装置】

|

| [Keep evenness controled warp tension by ELO electricity send warp device] |

| ELO电控送经装置利用设置在张力辊部的测力传感器检测出实际的张力,并通过计算机处理及其指令驱动反应速度超群的AC伺服马达,控制经轴的送经。同时对于经轴直径的变化进行自动的补偿,因此送经精度极高,可以恒定的保持均匀的经纱张力,确保出色的织物产品的质量。 |

| ELO electricity controls let off device detect fact tension by tension sensor under tension roll.And it control warp beam let off during drive AC servomotor by computer.Let off through diametral variety repair proceeding automatically,so it is very accuracy,can invariable keep warp tension,insure outstanding quantity of frabic. |

|

|

【不需要对梭口】

|

| [Do not adjust shed] |

| ELO电控送经装置还可以根据纺机停台时间的长短由计算机进行伸长的控制,通过经轴的反转(倒转)功能和织口控制功能控制织口的合适的位置。通过这一功能,可以消除停车档,进行高质量的织造。 |

| ELO electricity controls let off device can also console warp lengthening according to the stop time of loom by computer,control fit shed during reversal function.Pass this function,can eliminate weft crackiness,proceed high quality weaving. |

【积极松经装置】

|

| [Do not adjust shed] |

|

| 对由于经纱的开口而产生的经纱长度的变化,可以在开口时进行积极的补偿。对织口的稳定和确保打纬十分有效。 |

| For change of warp length during sheding,can active compensate.It is very valid for filling. |

【织口控制】

|

| [cloth fell control] |

| 在停机时缓和经纱的应力,通过再启动使织口复位,可以有效地防止在织造斜纹或缎纹时所产生的停车档。 |

| Loose warp while loom stop,then strain warp when start.It is valid to control weft crackiness when weave twill or stain. |

TAKE UP

|

【机械式连续间接卷取(MTU)】

|

| [Continuous indirect mechanical take up device(MTU)] |

| 由于采用了机械式间接卷取,因此可以在不停机的状态下进行落布。在卷取传动上使用了多板式的盘式制动器。从而消除了打滑现象和卷皱,使卷取平整。 |

| Because adopte continuous indirect mechanical take up device,therefore can fall cloth when running.Use friction shoe in take up dirve,so avoid skid and wrinkle and make cloth flattening. |

【电子式卷取装置】(选件)

|

| [electricity take up device(choose part)] |

|

| 采用AC伺服电机系统,使卷取和织机完全同步。打纬密度可在i键盘上进行设定而不要变换齿轮,同时可以进行变纬密织造。(ETU) |

SHEDDING

|

【消极凸轮机】

|

| [Negative cam] |

| 提高了零部件的耐久性,可以进行高速适应性强的经纱开口,是一种适应超高速的凸轮机。 |

| Adopt super-speed nagative cam in ZCM machine.Increases the enduring of the parts,can proceed super-speed adaptability shedding,it is a super-speed cam machine. |

【多臂开口】

|

| [Dobby shedding(choose part)] |

| 可选机械/电子、消极/积极以及上置/下置式多臂装置。 |

| Can choose the electronics type,negative type / positive type and underneath type / overhead type equipment. |

LENO

|

【行星式绞边装置】

|

| [The planet type leno equips] |

|

| 采用行星式齿轮方式的绞边装置,可以适应高速化。对于各部位的磨损采取了有效的措施,形成不发生松皱的坚固布边。 |

| The leno device of planet gear can adapt high speed.We adopt cure no risk at all for every part.Becoming the hard cloth side that do not take place the wrinkle. |

【短经自停装置】

|

| [Broken warp stop device] |

| 短经自停装置具有高灵敏度的反应,在经纱断头时可以立刻使织机停止。任为选择件,还有一种容易发现断经位置,显示列数的形式。 |

| Broken wrap stop device have high sensitivity ratio,while broken warp can make loom stop immediately.As a choose part,still having a kind of easy discover broken warp position,slowing that row position. |

电气控制 【Electric Control 】

|

| 为了满足喷气织机对高速化、通用化以及高质量的要求,将基本功能的控制全部统一在32位的主线板上,并对大容量的控制数据进行高速处理。高速的判断则利用和光通讯电缆相接的i键盘执行。 |

【易操作、高性能的人机接口...中文i键盘】

|

| [Easy operation,high performance man-machine interface...i keyboard...English,Indanisa] |

| I键盘上配备有高亮度液晶显示器,除可以自动显示运转信息、保全信息和织造长度的信息以外,还可以进行自动控制,自动条件设定和多功能的使用。画有示意图的操作键是以色和配置来区分不同的功能(保全工用、管理用和操作工用)。操作工所需的信息利用中央的3个键即可得到,使用简便性。另外,如配备连接单元,还可以成为与TCCs 等外部的主计算机进行对话的终端,进行双向通讯。4、6、8喷,电子控制任意选纬,适于普通及多色织造。 |

|

| Provide LCD i keyboard can clear seeing from any position.Excluding automatically showing running information,repairing information and clothing length,also can proceed autocontrol,automatic condition set and multi-function usage.Operation key of diagrammatic drawing are distinguish function by color and position.(fixer,manage and operator) Operator can attain massage by 3 center key,usage is quit simple.Moreover,if equipment connect unit,it also can become dialogue termination with the exterior computer,proceeding both way communication. |

【计数功能】

|

| [Count function] |

| 织造长度可以用米或码显示。还可以显示下次落布的预测时间和了机的预测时间。 |

|

| Unit of cloth length can use meter or yard.Also can show forecast time of the next cloth and forecast time of warpout. |

【停车原因显示】

|

| [Stop cause showing] |

| 当织机由于故障停车时,通过自我诊断功能可以将检查项目和需要更换的部分显示出来。在停车时,显示停车原因和停车时间。 |

| When loom stop that occur trouble,the loom can show check item and repair part.While stop,it show stop cause and stop time. |

【保全键】

|

| [Fixer key] |

| 当操作工呼叫保全工时使用。如按下一次该键,4色指示灯的红灯闪亮,再按下一次时红灯停止闪亮。 |

| It is used when opertor call fixer.If press,the red- lamp of four tower lamp flash, if press again,the red lamp stop flash. |

【便于携带的记忆卡系统】

|

| [Memory card system that convenience carry] |

| 这是将织机的设定条件写入记忆卡并进行保存的系统。还可以将记忆卡中的记录输入到其他织机上,并可以防止设定失误。如备有不同织物规格的记忆卡,还可以迅速进行织物品种的跟换。 |

|

| This is write loom craft into memory card and save.And can write craft from memory card to other loom.So not set by hand and avoid fault.If have the memory card of the different loom craft,can also proceed renewal variety quickly. |

【织机电脑监控及统计功能】

|

| 织布厂通过专用计算机网络,可以实现对每台织机的运算记录进行统计、汇总,从而实现工厂电脑集约化管理。 |

【色纱探纬器】(选件)

|

| [color weft feeler](choose part) |

| 反射式色纱探纬器可以可靠地探测所有纬纱的短纬和长纬,能够稳定地进行引纬,而且不需要穿筘幅专用的钢筘。 |

|

| The echo color weft feeler can check all of short and long pick,can stabilize filling,and do not need special reed. |

【全自动探纬控制器】(选件)

|

| [Auto-detection weft feelers](choose part) |

| 无需人工高速即可自动工作在灵敏度合适状态。 |

| Feelers may operate at high speed on the best state without the help of peope. |

|

|

【规格尺寸】

|

| [Dimensions] |

|

纺机筘幅(Reed Width) |

A |

B |

D |

W |

|

1900(75¨) |

1900 |

2540 |

1300 |

4320 |

|

2300(91¨) |

2300 |

2940 |

1700 |

4720 |

|

2500(98¨) |

2500 |

3140 |

1900 |

4920 |

|

2800(110¨) |

2800 |

3440 |

2000 |

5220 | |

【主要技术参数】

|

|

项目 |

规格 |

选配件 |

|

筘幅 |

公称筘幅:190、210、230、250、280、330、340、360、390cm |

|

|

有效筘幅:公称筘幅减0-60cm(190-250cm) |

公称筘幅减0-80cm |

|

公称筘幅减0-80cm (280cm以上) |

|

|

织造范围 |

短纤:120-5S/1 |

|

| 长丝:56D-600D |

|

|

纬纱选择 |

双喷专用9*9; |

双喷、四喷自由选纬 |

|

动力 |

通过电磁制动器直接控制定位停车 |

|

|

超起动马达3.0kw(凸轮开口)、3.7kw(多臂开口)、5.5kw(提花) |

|

|

双边按钮开关操作 |

|

|

引纬 |

主喷嘴、辅助主喷嘴、辅喷嘴、异形钢筘 |

延伸喷嘴 |

|

引纬控制:电磁阀(SVU) |

WBS纬纱拉直器 |

|

开口 |

消极式凸轮开口:多达8页综框 |

|

|

曲柄式连杆开口:4页或6页综框 |

|

|

积极式凸轮开口:多达8页综框 |

|

|

多臂开口:多达16页综框 |

|

|

大提花开口 |

|

|

送经 |

电控式连续积极送经(ELO) |

双经轴、双后梁 |

|

积极松经 |

|

|

经轴边盘直径 |

Ø800mm Ø1000mm Ø1100mm |

|

卷取 |

机械式连续卷取(MTU) |

电子卷取(ETU) |

|

纬密范围:25-205根/英寸(机械卷取),25-300根/英寸(电子卷取) |

|

|

卷布径:Ø600mm(凸轮、多臂、提花开口) Ø520mm(曲柄开口) |

大卷装Ø800mm |

|

打纬 |

曲柄式多筘座脚打纬机构 |

|

|

四连杆打纬(190-280筘幅),六连杆打纬(280-390筘幅) |

|

|

配备摇轴中间支撑架、摇摆平衡器 |

|

|

测长储纬 |

电子鼓筒式储纬器(FDP) |

直排震动式 |

|

纬纱架 |

落地式4只筒纱(2喷),落地式8只筒纱(4喷) |

|

|

布边 |

行星齿轮式咬边装置 |

|

|

纱端处理 |

弃边卷取3只齿轮式 |

|

|

剪纬 |

机械式剪刀 |

自动式 |

|

润滑 |

主传动部分为油浴方式、手动集中供油(黄油) |

自动集中供油 |

|

停车装置 |

纬纱:光电式探纬器、双探头 |

|

|

经纱:电气接触式6列停经片 LED显示列 |

|

|

其他:绞边纱、弃边纱断头自停 |

|

|

停车原因显示:在i键盘显示信息,多功能4色LED灯停车显示 |

|

|

自动化 |

控制:多功能微机控制系统,具有参数设定/控制/监控/自我诊断/人工智能界面 |

|

|

找断纬装置:自动找梭口(APF) |

|

|

通过变频器作慢点动(正反转) |

|

|

其他:监控器输出端子 |

集中监控管理系统 |

|

记忆卡系统 |

|

|

喷射自动控制(AJC) |

自动气压控制 | |

[Main technique parameter]

|

|

Item |

Specification |

Optional |

|

Reed Space |

Norminal:190、210、230、250、280、330、340、360、390cm |

|

|

Useful reeding width:same as nominal width maximum reduction:80cm |

|

|

Yarn range |

Spun:Ne 100-Ne5 |

|

| Filament:56D-600D |

|

|

Welf Seletion |

2-color mixing, 2-color at-will,4 colors,6 colors |

|

|

Drive |

Direct start of rush-start motor dirve |

|

|

Motor power: 3.0kw(cam shedding)、3.7kw(dobby shedding)5.5kw (jacquard) |

|

|

Push-button operetion with both hands |

|

|

Welf Insertion |

Main and sub-nozzles combined system |

Stretch nozzle |

|

Profile reed |

|

|

Auxiliary main nozzle |

|

|

Shedding |

Crank plain shedding:Shaft number:4 |

|

|

Positive cam shedding:Shaft number up to 8 |

|

|

Negative cam shedding:Shaft number up to 8 |

|

|

Dobby shedding(Electronic,Positive,Floor-mounted): Shaft number up to 16 |

|

|

Jacquard shedding |

|

|

Let-off |

Electronic let-off(ELO),with kickback function |

|

|

Twin beam |

|

|

Negative easing |

|

| Flange dia,Ø800mm |

|

|

Take-up |

MTU Mechanical take-up |

|

|

Pick density:25-205 picks/inch(MTU),25-300picks/inch(ELO) |

Electronic take-up |

|

Max,take-up diameter: Ø600mm(Cam,dobby,Jacquard shedding)Ø520mm (crank shedding) |

|

|

Beating |

Carnk type beationg,multiple sley sword beation |

|

|

4 links(Reed space up to 230cm),6 links(Reed space 250cm or more) |

|

|

Measuring/storing |

FDP free Drum Plloing |

|

|

Filling supply stand |

Floor Mounted for 4 pacdages(2 colors),Floor Mounted for 8 packages(4 colors) |

|

|

Selvedge |

Planetary gear motion |

|

|

Waste Filling Removal |

Catch cord type(3-roll type),catch cord type(Gear type) |

|

|

Cutter |

Mechanical cutter |

|

|

Lubrication |

Oil bath system for main driving parts,centralized lubrication (Manual grease) |

Central oil filling system |

|

Auto-stop Motion |

Filling yarn:Reflective weft feeler |

|

|

Warp yarn:Electric 6-row contact bar system |

|

|

Others:Stop notion for selvage and catch cord yarn |

|

|

Stop cause indication:Indication by message on Navi-Board |

|

|

Auto-Matical |

With i-Board(Data setting,automatic control,monitoring,self- diagnosis function) |

|

|

Pick finding:APF Automatic Pick Finder |

|

|

Slow inching by inverter(Forward,reverse) |

|

|

Monitor output terminal |

|

|

Memory card system |

|

|

Automatic jetting control |

| |